Plastic Processing

Our products find their way into many different application areas within the plastic processing industry: film, blow molding, injection molding, extrusion to name the most dominant ones.

Partner Products understands the characteristics and requirements of the different market segments but at the end of the day we boil it down to fulfill our core mission – increase customer value

Cost and Performance

High quality, high quantity film production requires raw materials and additives that work well together and provides optimal performance

High Speed Production

Regardless of production process Partner Products provides Masterbatches that secures a high speed production process

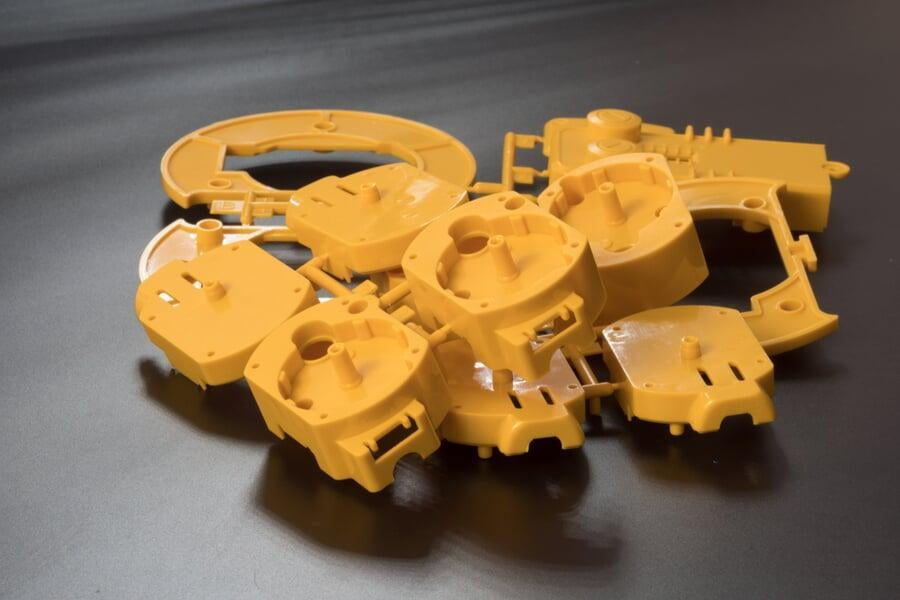

Simple Yet Complex

Partner Products provides Masterbatches that reduce cycle time, stabilizes the process and improves injection molded products

Long Lasting Performance

Pipe material need to have exceptional strength and toughness, the ability to withstand harsh environmental conditions for prolonged time and resist cracking

Through Thick and Thin

Partner Products supplies additive Masterbatches for sheet extrusion that aids in managing the melt, improves productivity and adds value to the finished product

Take away the Pressure

Complex shapes, affordable tooling and uniform wall thickness makes a strong case for rotational molding. Partner Products have the Masterbatches that improves the odds even more